Single Line Mechanical TOF LiDAR Applications in Intelligent Bulk Material Management

LiDAR is an acronym for "light detection and ranging". Its working principle is the system emits a detection laser beam to the target, and then receives the return signal reflected by the target, and performs high-speed processing on ToF of laser, and obtains the real 3D point cloud scene and information: distance, speed, orientation, shape, size, attitude, etc.

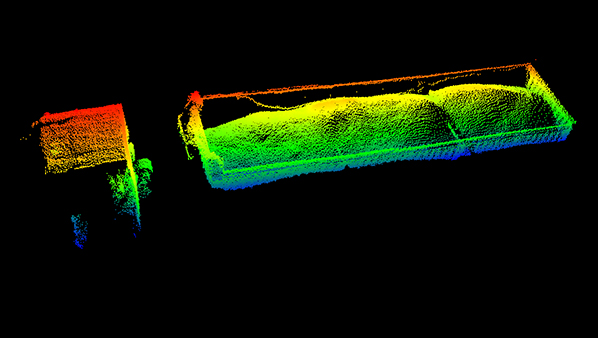

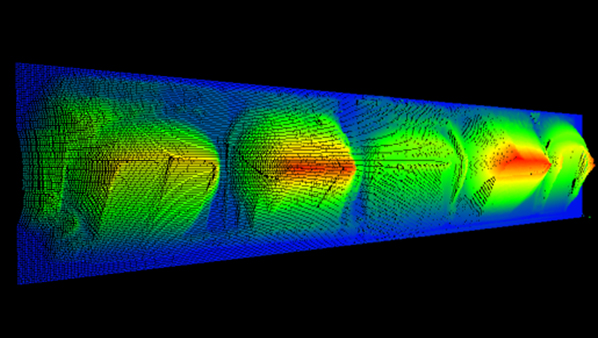

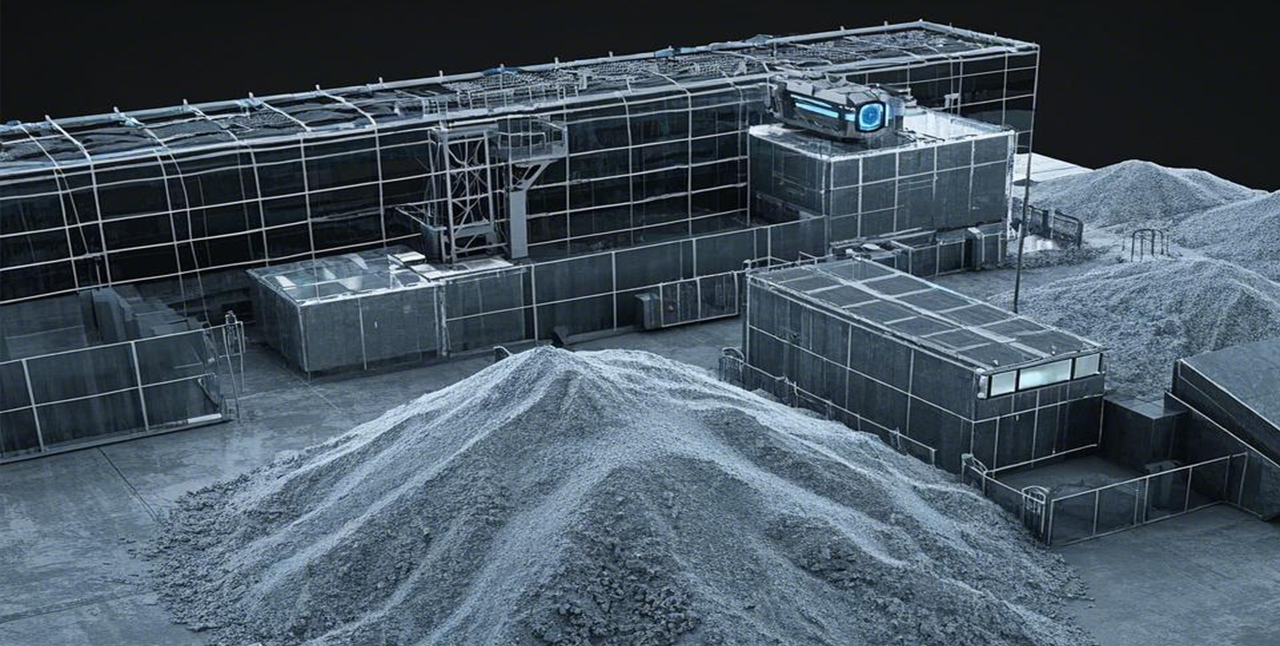

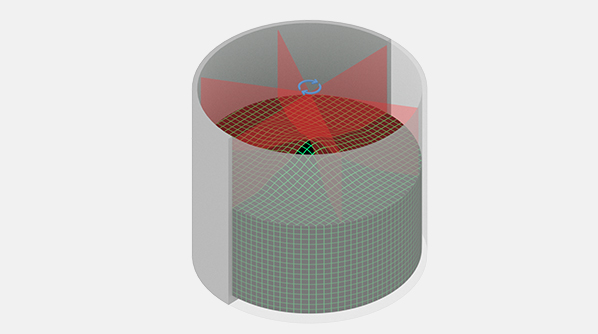

The utilization of LiDAR technology excels in precise bulk material volume inventory, whether it be for mineral resources such as coal, iron, aluminum, or grain storage. Its efficiency ensures accurate inventory management in silo level detection. Simultaneously, LiDAR technology also demonstrates outstanding real-time precision in conveyor belt flow detection, providing reliable data support for production processes.

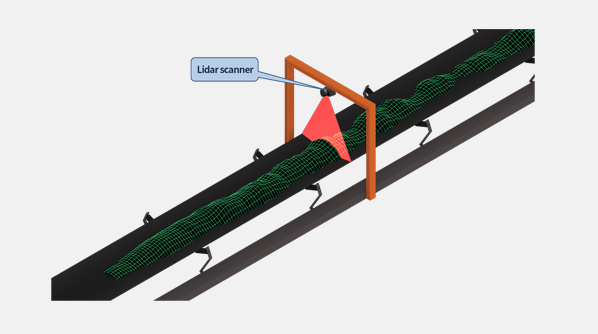

Level Scanning

Flow Scanning

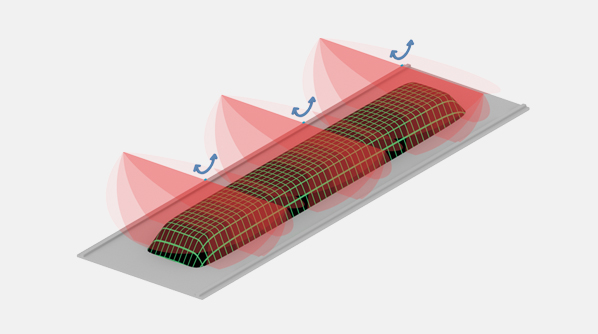

Oscillating scan

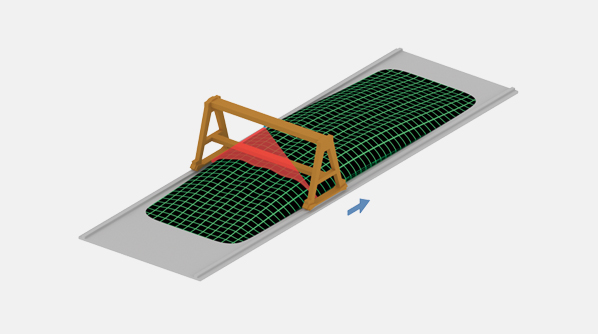

Mobile Scanning

© Copyright Baoding Galaxy Electronic Technology Co.,Ltd. 2024. All rights reserved.冀ICP备05000380号-1 Privacy Policy

Design by: Bjszhd